In a production process, we use the term ‘productivity’ to describe the ratio of output to inputs. It is seen as one of the most important aspects to a business as customers demand high quality machined parts with fast turnaround. Geometric Manufacturing are continually investing in the productivity of staff, facilities and methods to increase efficiency of the business and aid meeting the demands of our customers needs.

Productivity

Geometric Manufacturing’s investment to Productivity

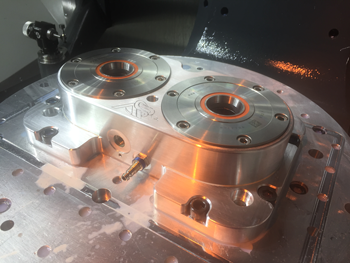

Having been established for over 30 years in the engineering industry, we recognise the importance of quality & delivery which is why we have been continually re-investing in the productivity of our business overall. Examples of this include the need to invest in newer & better equipment which we have done by purchasing a number of HAAS 3-Axis and 5-Axis machinery.

The business is recognising the need to become more productive for cost-saving efficiency for our clients. We are continuing to train staff as much as possible so they gain vital skills and can make decisions when they need to.

Methods of Productivity

Our management team have understood the real need for correct structure within our business and hiring specific skillsets such as quality engineers and inspection specialists to maintain a high quality level for completed parts.

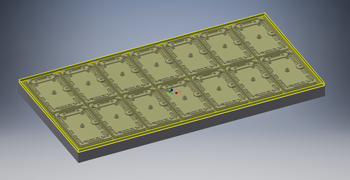

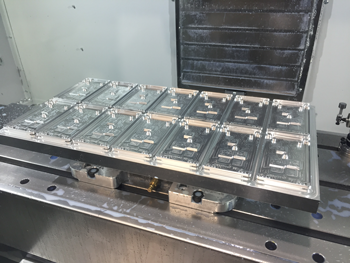

Not only this but Geometric Manufacturing are re-investing back into the business and producing solutions to be able to change parts within machines much faster and cut in bulk so the machining process is more engineered, but more efficiently engineered.

Interested in finding out more? Click the button below to get in touch.